Heat treated pallets are essential for safe and compliant international shipping. They undergo a specific heat process to eliminate pests, ensuring the wood is free from harmful organisms. This treatment helps meet global shipping regulations, ensuring smoother customs clearance and protecting global ecosystems. This article will explore the key benefits of using heat treated pallets and their significance in international trade.

Key Takeaways

- Heat treated pallets are essential for international shipping, ensuring compliance with ISPM-15 standards and preventing pest spread, thereby safeguarding global agriculture.

- The heat treatment process enhances the durability of pallets, reduces shipping costs through weight reduction, and offers an eco-friendly alternative to chemical fumigation, ensuring health safety.

- Choosing a reliable supplier for heat treated pallets is crucial for maintaining compliance with shipping regulations and ensuring the quality and consistency of the pallets.

What Are Heat Treated Pallets?

Heat treated pallets, also known as ht pallets or export pallets, are wooden pallets subjected to a specific heat treatment process to eliminate pests and ensure product quality. The process requires heating the pallets to a minimum of 140 degrees Fahrenheit. This must be maintained for at least 30 minutes. The primary purpose of heat treating pallets is to eradicate any pests that might be residing in the wood, thereby ensuring hygiene and safety during international shipping. Additionally, a heat treated pallet is essential for compliance with shipping regulations.

Heat treated wood pallets offer more than just pest elimination; they are environmentally friendly and meet global shipping standards. Using heat instead of chemicals ensures no harmful residues, making them safer for handlers and consumers. Consequently, these pallets are a sustainable and reliable option for businesses transporting goods internationally.

Why Heat Treating Wood Pallets is Essential for International Shipping

Compliance with regulations is crucial in international shipping. Heat treating wood pallets is necessary to meet these regulations and ensure the safe transport of goods. Untreated wood pallets can carry pests and diseases, risking ecosystems and agriculture in the destination country. Thus, heat treatment is not just regulatory but critical for safeguarding global plant health.

Heat treated pallets are vital for international shipments as they comply with the ISPM-15 standard, which mandates treating wood packaging materials to prevent pest spread. Non-compliance can lead to delays or shipment destruction at ports. Using heat treated pallets ensures smooth customs navigation and timely delivery.

Using heat treated pallets aligns with international shipping regulations by eliminating pests and ensuring compliance with phytosanitary standards. This helps protect global agriculture and ecosystems, facilitating smoother international trade and promoting sustainable, responsible shipping practices.

Understanding ISPM-15 Standards

ISPM-15 is an international standard specifically designed to address the treatment requirements for wood packaging materials in international shipping. The main goal of ISPM-15 is to protect global plant health by preventing the introduction and spread of pests. This standard, in effect since 1993, outlines specific heat treatment criteria, including the allowable amount of bark on treated pallets.

ISPM-15 compliance is crucial for businesses in international trade. Selecting a reliable supplier adhering to these standards and having quality assurance processes is vital. Meeting ISPM-15 requirements protects plant health and facilitates seamless international shipments by minimizing delays and rejections at customs.

Role of the International Plant Protection Convention (IPPC)

The International Plant Protection Convention (IPPC) plays a pivotal role in enforcing ISPM-15 standards and preventing the spread of harmful plant pests and diseases globally. By mandating the treatment of wood packaging materials, including heat treatment, the IPPC aims to mitigate the risk of pest transportation across borders. This is vital for protecting global plants health and ensuring the safety of plant products being transported internationally.

Adhering to IPPC standards safeguards agriculture and ecosystems while facilitating smoother international trade by reducing pest-related inspection delays. The heat treatment process, a critical component of these standards, eliminates pests in wood packaging, ensuring compliance with international regulations and contributing to global plant health protection.

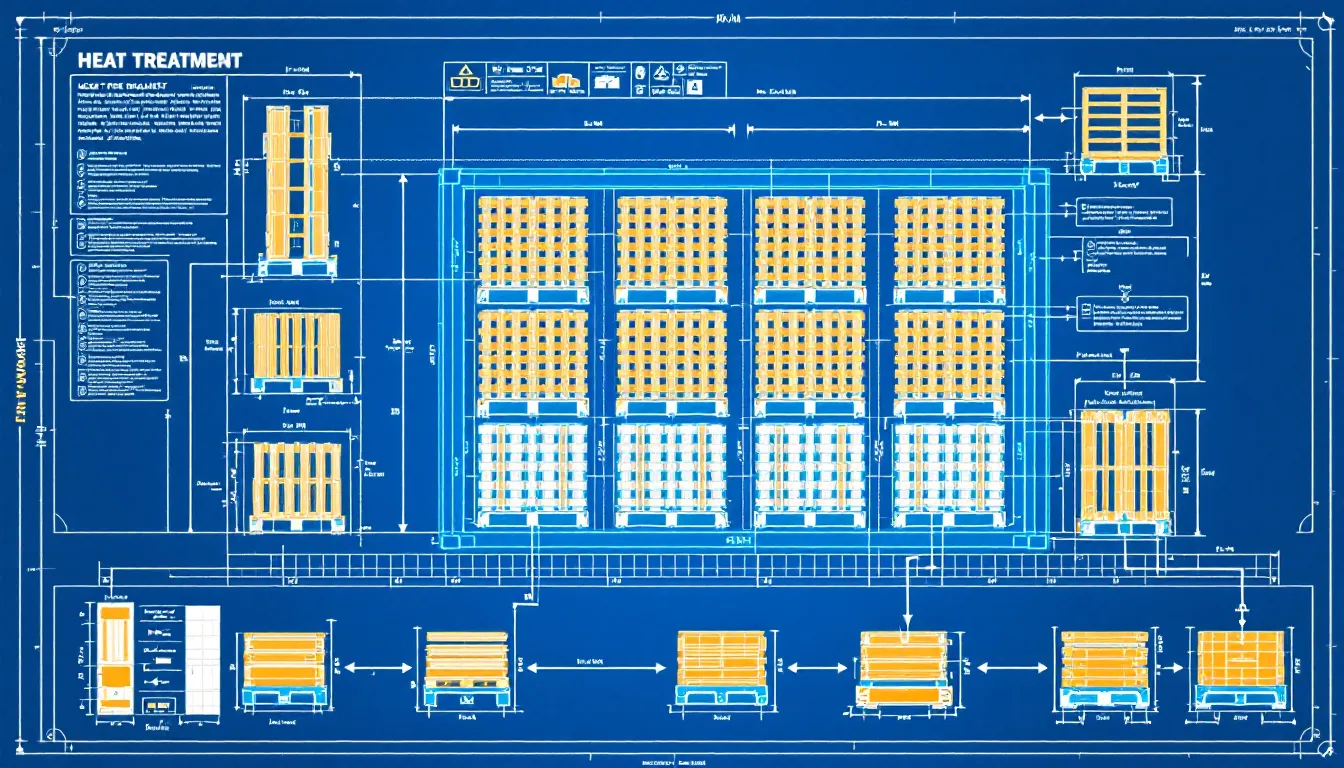

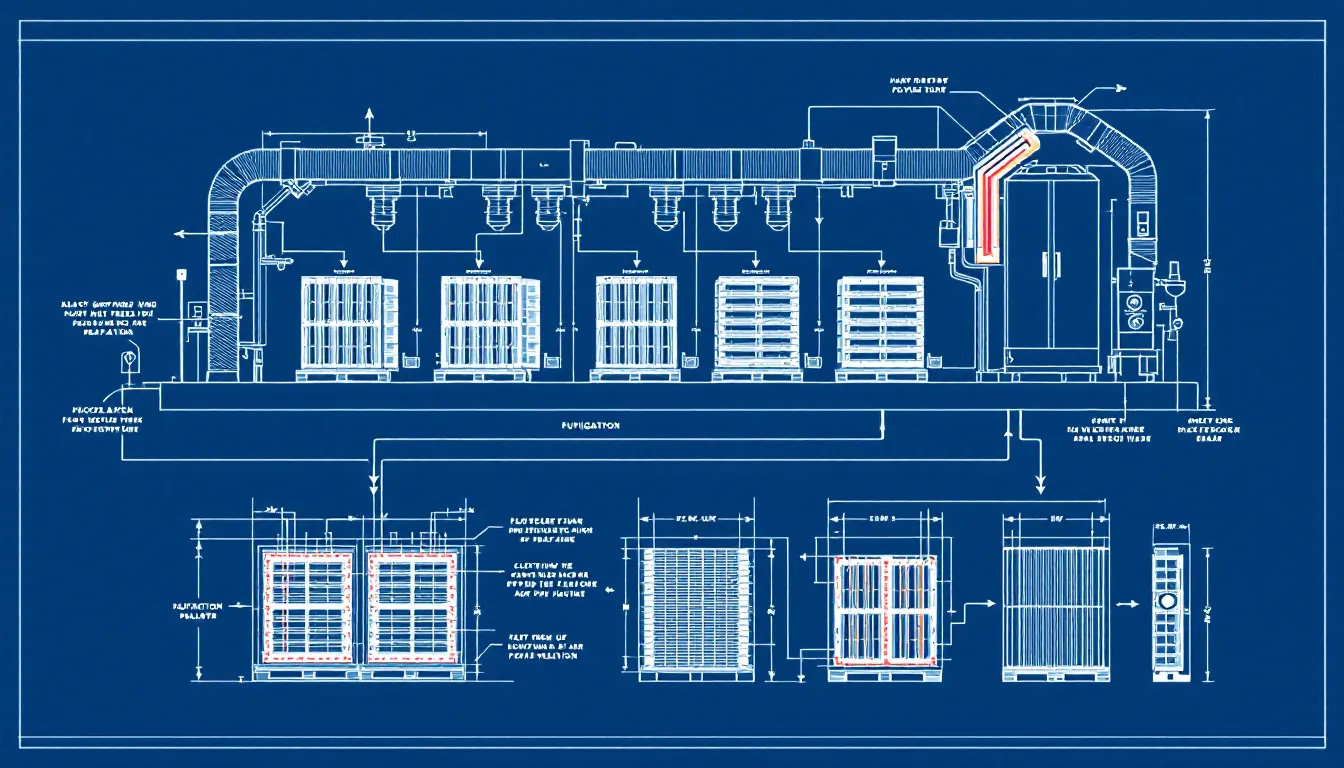

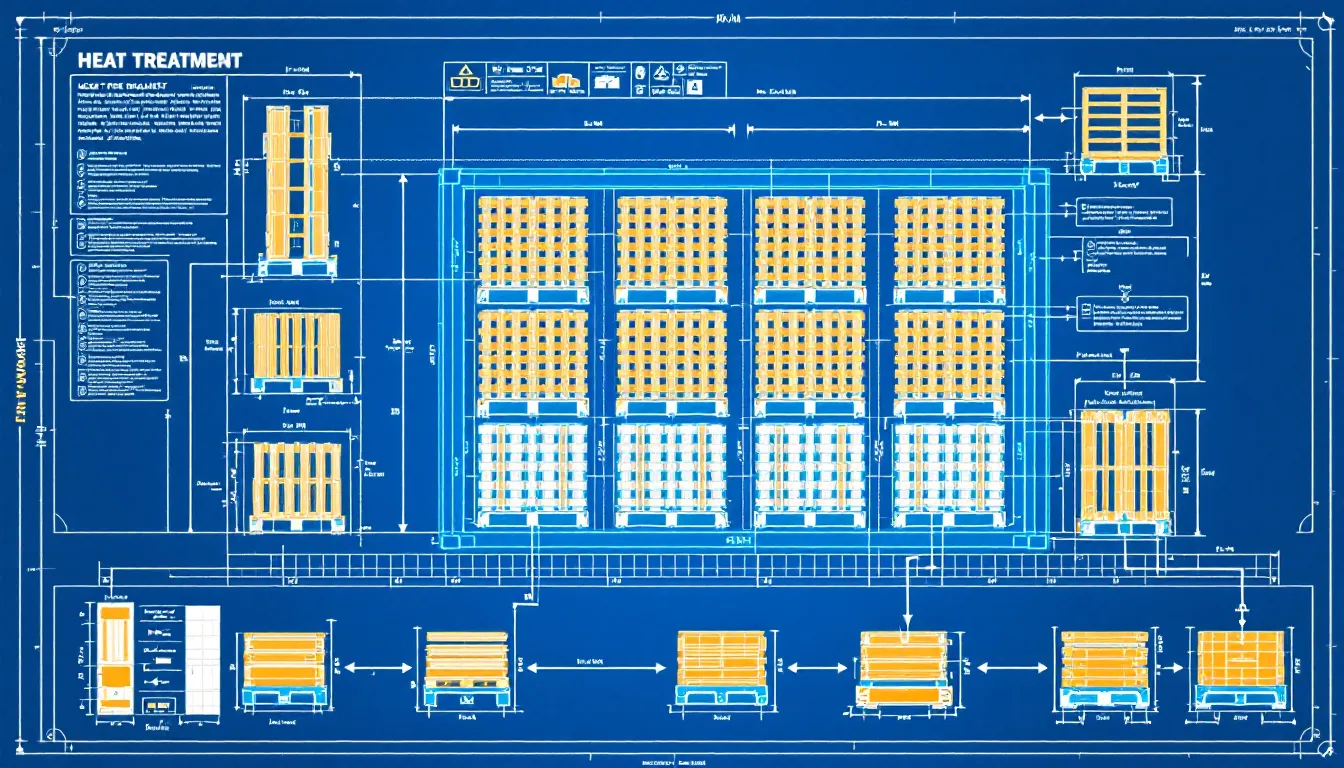

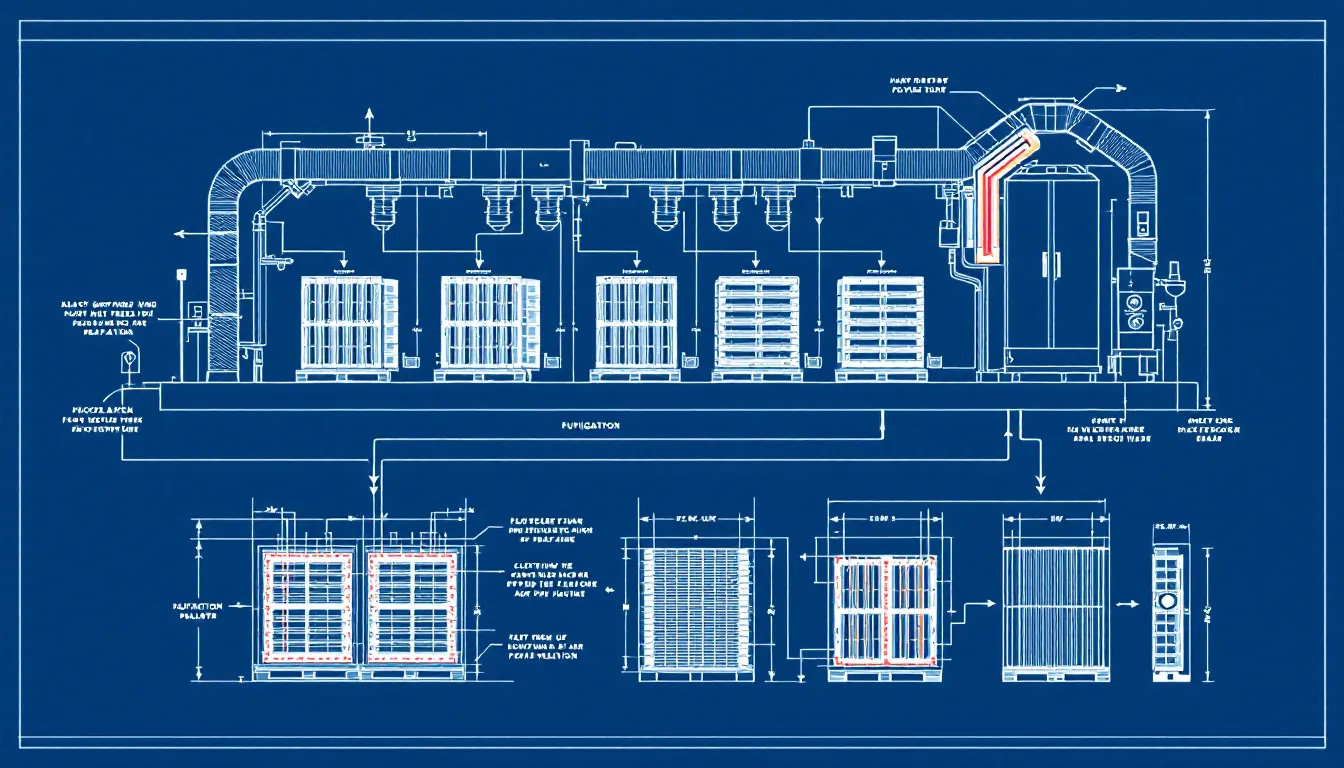

The Process of Heat Treating Pallets

The process of heat treating pallets is designed to adhere to the phytosanitary process that prevents the spread of pests during international transport. This involves raising the wood’s temperature to effectively eliminate pests and pathogens, ensuring compliance with international standards.

The process is comprehensive and involves several critical steps to ensure the pallets are treated thoroughly and effectively.

Debarking and Inspection

The heat treatment process begins with debarking and inspection. Debarking removes insect eggs and other contaminants, initiating the decontamination process by eliminating insects, larvae, and other potential pests in the bark to break down any remaining threats.

After debarking, inspection ensures the pallets comply with guidelines and are free from defects that could compromise heat treatment. This thorough inspection ensures only high-quality pallets proceed, maintaining treatment integrity and compliance with international standards.

Heat Treatment Procedure

The core of the heat treatment process involves:

- Subjecting the pallets to high temperatures using a large kiln or oven.

- Maintaining the pallets at a temperature of 140 degrees Fahrenheit for at least 30 minutes to ensure effective pest elimination.

- Confirming the temperature by inserting a temperature gauge into the wood to verify that the required internal temperature is reached.

Proper airflow and heat distribution are achieved by carefully arranging pallets in the kiln, ensuring even heat penetration and effective eradication of pests and pathogens. Monitoring internal temperature with thermocouples ensures thorough treatment and compliance with phytosanitary standards.

Various kilns, including those with forced-air systems, may be used to enhance heat circulation. Regardless of the method, the goal is to effectively eliminate pests and bacteria, ensuring the treated pallets are safe and compliant for international shipping.

Marking and Certification

Once the heat treatment process is complete, the pallets must be marked and certified to indicate compliance with ISPM-15 standards. This involves marking the pallets with a specific stamp that includes an internationally recognized code for heat treatment. These markings are crucial for certification and compliance with international shipping regulations.

The stamp includes details like the country code and a registration number, aiding in compliance verification and traceability. Proper certification may require additional documentation to confirm the pallets meet treatment standards, ensuring safe acceptance in stamped countries and smooth customs clearance.

Key Benefits of Using Heat Treated Pallets

Using heat treated pallets offers numerous benefits that go beyond mere compliance with international regulations. These benefits include:

- Enhanced durability

- Cost efficiency

- Improved environmental and health safety

- Elimination of pests

- Reduced risk of damage to cargo caused by pests

- Compliance with ISPM-15 standards, helping prevent the spread of pests through regulated wood packaging materials

- Facilitation of global trade

Heat treated pallets are recognized globally, enabling exporters to access more markets without phytosanitary restrictions. Their benefits include:

- Leaving no harmful chemical residues, making them safer for handlers and consumers

- Offering reliability and sustainability

- Being ideal for businesses transporting goods internationally Unlike fumigated pallets, heat treated pallets provide these advantages.

Durability and Strength

The heat treatment process not only kills pests but also enhances the structural integrity of the pallets. By reducing the moisture content in the wood, heat treated pallets become more durable and less prone to decay during transport. This increased durability means that the pallets can withstand the rigors of international shipping, ensuring that your goods remain safe and secure throughout their journey.

Heat treating extends the life of pallets by reducing pest issues, making them more cost-effective long-term. Their durability also makes them reusable, providing additional savings and reducing the need for frequent replacements.

Overall, heat treated pallets offer a robust and reliable solution for shipping needs, ensuring that your goods arrive in optimal condition.

Cost Efficiency in Shipping

One of the significant financial benefits of using heat treated pallets is their cost efficiency in shipping, which includes:

- The heat treatment process reduces the moisture content in the pallets.

- This reduction leads to a decrease in overall weight.

- Lighter pallets result in significant cost savings through reduced shipping weights.

- Reduced shipping weights can lower freight costs.

Weight reduction in pallets also decreases shipping costs, making them more economical for businesses in international shipping. Choosing heat treated pallets results in lower transportation costs, improving the bottom line and ensuring a cost-effective shipping process.

Environmental and Health Safety

The heat treatment process is recognized as an eco-friendly alternative to chemical fumigation. Choosing heat treated pallets over chemical treatments reduces environmental impact and mitigates health risks associated with toxins. This method is widely accepted in the pallet industry for its safety for both the environment and workers.

Heat treated pallets offer several advantages over chemically treated ones:

- They pose fewer health risks.

- They minimize risks associated with alternative chemical treatments.

- They enhance wood resistance to mold, fungi, and decay.

Overall, they contribute to a safer environment and better health outcomes for consumers and the world.

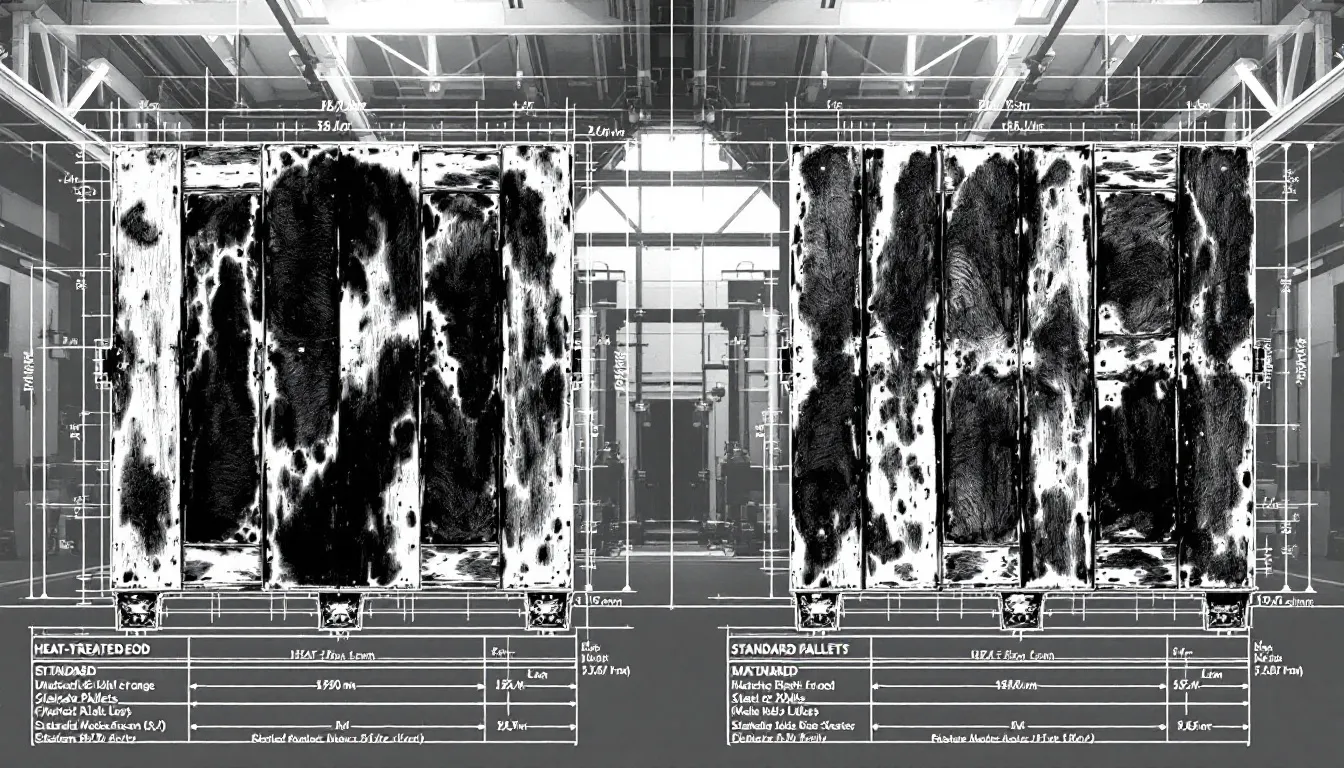

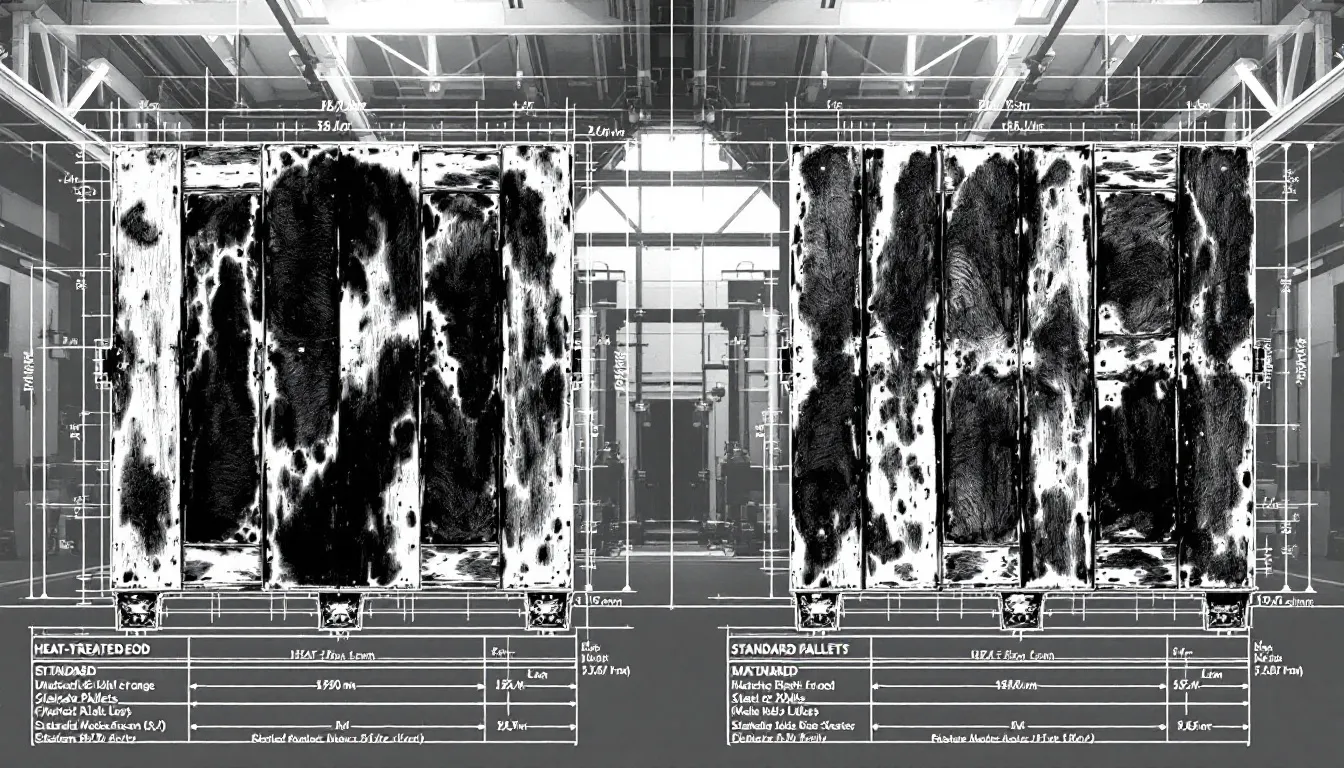

Comparing Heat Treated Pallets to Fumigated Pallets

When comparing heat treated pallets to fumigated pallets, the differences in health risks, environmental impact, and durability become evident. Health risks associated with heat treated pallets are minimal compared to fumigated pallets, which involve exposure to methyl bromide that can cause serious health issues. Additionally, fumigated pallets pose a risk to the environment due to the use of methyl bromide, which is known to damage the ozone layer and increase UV radiation.

Both heat treating and fumigating are methods to eliminate pests from wood pallets, but heat treating is preferred because:

- It does not involve toxic chemicals.

- It enhances pallet durability by reducing moisture content.

- It makes pallets less prone to decay compared to fumigated pallets.

Overall, heat treated pallets offer a safer, more environmentally friendly, and durable wood solution for ship shipping needs.

Export Compliance with Heat Treated Pallets

Heat treated pallets are primarily utilized for exporting goods outside of the United States. These pallets help mitigate delays and costs associated with customs rejections by ensuring compliance with international pest control standards. Compliance with international shipping standards is simpler with heat treated pallets as restrictions on chemical treatments like methyl bromide increase.

After treatment, the pallets receive an IPPC stamp indicating compliance with international standards. The IPPC stamp includes a country code and a registration number for traceability. These markings indicate compliance with ISPM-15 standards after heat treatment, ensuring that the pallets can be safely accepted in international markets and facilitating smooth customs clearance.

How Long Does Heat Treatment Last?

The longevity of heat treated pallets can range from 3 to 10 years based on usage and storage conditions. The heat treatment lasts for the lifetime of the wood pallet, ensuring continued compliance and safety throughout its use. However, if a part of the wood pallet is removed and repaired, it is no longer considered certified and needs re-treatment to ensure compliance and integrity.

Re-treatment is essential to maintain the effectiveness of the heat treatment and to ensure that the pallets continue to meet international standards. By adhering to these guidelines, businesses can ensure that their pallets remain compliant and effective for as long as possible, providing a reliable solution for their shipping needs.

Choosing the Right Supplier for Heat Treated Pallets

Choosing the right supplier for heat treated pallets is crucial for compliance with shipping regulations and maintaining high-quality standards. A reliable supplier should adhere to ISPM-15 standards and have the necessary export certifications. Understanding the supplier’s production capacity, including daily output and scalability, helps avoid delays and ensures consistent fulfillment of shipping needs.

Additionally, it is vital to inquire about the types of pallets a supplier offers, including their options for new, recycled, and heat-treated pallets. Having a dedicated account manager and prompt response times for inquiries can significantly improve the supplier-client relationship and ensure that any contact issues are addressed swiftly.

By carefully selecting a supplier that meets these criteria, business can ensure that they receive high-quality, compliant heat treated pallets that meet their shipping needs.

Summary

In conclusion, heat treated pallets are an essential component of modern shipping solutions, offering numerous benefits such as enhanced durability, cost efficiency, and improved environmental and health safety. Compliance with international standards like ISPM-15 ensures that goods can be transported safely and efficiently across borders, protecting global agriculture and ecosystems. By understanding the process of heat treating pallets and choosing the right supplier, businesses can optimize their shipping operations and ensure the safe and compliant transport of their goods. Embracing heat treated pallets not only safeguards your cargo but also contributes to a more sustainable and responsible global trade environment.

Frequently Asked Questions

What is the primary purpose of heat treating pallets?

The primary purpose of heat treating pallets is to eliminate pests, ensuring product quality, hygiene, and safety in international shipping. This process is essential for compliance with international regulations.

What temperature and duration are required for effective heat treatment of pallets?

To ensure effective pest elimination, pallets must be heated to at least 140 degrees Fahrenheit for a minimum of 30 minutes.

What is ISPM-15 and why is it important?

ISPM-15 is an international standard that requires the treatment of wood packaging materials to prevent pest spread, making compliance essential for safe international shipping. This standard helps protect ecosystems and agriculture across borders.

How long does the heat treatment last on pallets?

The heat treatment on pallets lasts for their entire lifetime, which can be between 3 to 10 years, depending on usage and storage conditions.

What are the environmental benefits of using heat treated pallets over fumigated pallets?

Heat treated pallets offer significant environmental benefits by avoiding toxic chemicals like methyl bromide, thus minimizing health risks and environmental damage. Furthermore, they improve the wood’s resistance to mold, fungi, and decay, contributing to sustainability.

Heat treated pallets are essential for safe and compliant international shipping. They undergo a specific heat process to eliminate pests, ensuring the wood is free from harmful organisms. This treatment helps meet global shipping regulations, ensuring smoother customs clearance and protecting global ecosystems. This article will explore the key benefits of using heat treated pallets and their significance in international trade.

Key Takeaways

- Heat treated pallets are essential for international shipping, ensuring compliance with ISPM-15 standards and preventing pest spread, thereby safeguarding global agriculture.

- The heat treatment process enhances the durability of pallets, reduces shipping costs through weight reduction, and offers an eco-friendly alternative to chemical fumigation, ensuring health safety.

- Choosing a reliable supplier for heat treated pallets is crucial for maintaining compliance with shipping regulations and ensuring the quality and consistency of the pallets.

What Are Heat Treated Pallets?

Heat treated pallets, also known as ht pallets or export pallets, are wooden pallets subjected to a specific heat treatment process to eliminate pests and ensure product quality. The process requires heating the pallets to a minimum of 140 degrees Fahrenheit. This must be maintained for at least 30 minutes. The primary purpose of heat treating pallets is to eradicate any pests that might be residing in the wood, thereby ensuring hygiene and safety during international shipping. Additionally, a heat treated pallet is essential for compliance with shipping regulations.

Heat treated wood pallets offer more than just pest elimination; they are environmentally friendly and meet global shipping standards. Using heat instead of chemicals ensures no harmful residues, making them safer for handlers and consumers. Consequently, these pallets are a sustainable and reliable option for businesses transporting goods internationally.

Why Heat Treating Wood Pallets is Essential for International Shipping

Compliance with regulations is crucial in international shipping. Heat treating wood pallets is necessary to meet these regulations and ensure the safe transport of goods. Untreated wood pallets can carry pests and diseases, risking ecosystems and agriculture in the destination country. Thus, heat treatment is not just regulatory but critical for safeguarding global plant health.

Heat treated pallets are vital for international shipments as they comply with the ISPM-15 standard, which mandates treating wood packaging materials to prevent pest spread. Non-compliance can lead to delays or shipment destruction at ports. Using heat treated pallets ensures smooth customs navigation and timely delivery.

Using heat treated pallets aligns with international shipping regulations by eliminating pests and ensuring compliance with phytosanitary standards. This helps protect global agriculture and ecosystems, facilitating smoother international trade and promoting sustainable, responsible shipping practices.

Understanding ISPM-15 Standards

ISPM-15 is an international standard specifically designed to address the treatment requirements for wood packaging materials in international shipping. The main goal of ISPM-15 is to protect global plant health by preventing the introduction and spread of pests. This standard, in effect since 1993, outlines specific heat treatment criteria, including the allowable amount of bark on treated pallets.

ISPM-15 compliance is crucial for businesses in international trade. Selecting a reliable supplier adhering to these standards and having quality assurance processes is vital. Meeting ISPM-15 requirements protects plant health and facilitates seamless international shipments by minimizing delays and rejections at customs.

Role of the International Plant Protection Convention (IPPC)

The International Plant Protection Convention (IPPC) plays a pivotal role in enforcing ISPM-15 standards and preventing the spread of harmful plant pests and diseases globally. By mandating the treatment of wood packaging materials, including heat treatment, the IPPC aims to mitigate the risk of pest transportation across borders. This is vital for protecting global plants health and ensuring the safety of plant products being transported internationally.

Adhering to IPPC standards safeguards agriculture and ecosystems while facilitating smoother international trade by reducing pest-related inspection delays. The heat treatment process, a critical component of these standards, eliminates pests in wood packaging, ensuring compliance with international regulations and contributing to global plant health protection.

The Process of Heat Treating Pallets

The process of heat treating pallets is designed to adhere to the phytosanitary process that prevents the spread of pests during international transport. This involves raising the wood’s temperature to effectively eliminate pests and pathogens, ensuring compliance with international standards.

The process is comprehensive and involves several critical steps to ensure the pallets are treated thoroughly and effectively.

Debarking and Inspection

The heat treatment process begins with debarking and inspection. Debarking removes insect eggs and other contaminants, initiating the decontamination process by eliminating insects, larvae, and other potential pests in the bark to break down any remaining threats.

After debarking, inspection ensures the pallets comply with guidelines and are free from defects that could compromise heat treatment. This thorough inspection ensures only high-quality pallets proceed, maintaining treatment integrity and compliance with international standards.

Heat Treatment Procedure

The core of the heat treatment process involves:

- Subjecting the pallets to high temperatures using a large kiln or oven.

- Maintaining the pallets at a temperature of 140 degrees Fahrenheit for at least 30 minutes to ensure effective pest elimination.

- Confirming the temperature by inserting a temperature gauge into the wood to verify that the required internal temperature is reached.

Proper airflow and heat distribution are achieved by carefully arranging pallets in the kiln, ensuring even heat penetration and effective eradication of pests and pathogens. Monitoring internal temperature with thermocouples ensures thorough treatment and compliance with phytosanitary standards.

Various kilns, including those with forced-air systems, may be used to enhance heat circulation. Regardless of the method, the goal is to effectively eliminate pests and bacteria, ensuring the treated pallets are safe and compliant for international shipping.

Marking and Certification

Once the heat treatment process is complete, the pallets must be marked and certified to indicate compliance with ISPM-15 standards. This involves marking the pallets with a specific stamp that includes an internationally recognized code for heat treatment. These markings are crucial for certification and compliance with international shipping regulations.

The stamp includes details like the country code and a registration number, aiding in compliance verification and traceability. Proper certification may require additional documentation to confirm the pallets meet treatment standards, ensuring safe acceptance in stamped countries and smooth customs clearance.

Key Benefits of Using Heat Treated Pallets

Using heat treated pallets offers numerous benefits that go beyond mere compliance with international regulations. These benefits include:

- Enhanced durability

- Cost efficiency

- Improved environmental and health safety

- Elimination of pests

- Reduced risk of damage to cargo caused by pests

- Compliance with ISPM-15 standards, helping prevent the spread of pests through regulated wood packaging materials

- Facilitation of global trade

Heat treated pallets are recognized globally, enabling exporters to access more markets without phytosanitary restrictions. Their benefits include:

- Leaving no harmful chemical residues, making them safer for handlers and consumers

- Offering reliability and sustainability

- Being ideal for businesses transporting goods internationally Unlike fumigated pallets, heat treated pallets provide these advantages.

Durability and Strength

The heat treatment process not only kills pests but also enhances the structural integrity of the pallets. By reducing the moisture content in the wood, heat treated pallets become more durable and less prone to decay during transport. This increased durability means that the pallets can withstand the rigors of international shipping, ensuring that your goods remain safe and secure throughout their journey.

Heat treating extends the life of pallets by reducing pest issues, making them more cost-effective long-term. Their durability also makes them reusable, providing additional savings and reducing the need for frequent replacements.

Overall, heat treated pallets offer a robust and reliable solution for shipping needs, ensuring that your goods arrive in optimal condition.

Cost Efficiency in Shipping

One of the significant financial benefits of using heat treated pallets is their cost efficiency in shipping, which includes:

- The heat treatment process reduces the moisture content in the pallets.

- This reduction leads to a decrease in overall weight.

- Lighter pallets result in significant cost savings through reduced shipping weights.

- Reduced shipping weights can lower freight costs.

Weight reduction in pallets also decreases shipping costs, making them more economical for businesses in international shipping. Choosing heat treated pallets results in lower transportation costs, improving the bottom line and ensuring a cost-effective shipping process.

Environmental and Health Safety

The heat treatment process is recognized as an eco-friendly alternative to chemical fumigation. Choosing heat treated pallets over chemical treatments reduces environmental impact and mitigates health risks associated with toxins. This method is widely accepted in the pallet industry for its safety for both the environment and workers.

Heat treated pallets offer several advantages over chemically treated ones:

- They pose fewer health risks.

- They minimize risks associated with alternative chemical treatments.

- They enhance wood resistance to mold, fungi, and decay.

Overall, they contribute to a safer environment and better health outcomes for consumers and the world.

Comparing Heat Treated Pallets to Fumigated Pallets

When comparing heat treated pallets to fumigated pallets, the differences in health risks, environmental impact, and durability become evident. Health risks associated with heat treated pallets are minimal compared to fumigated pallets, which involve exposure to methyl bromide that can cause serious health issues. Additionally, fumigated pallets pose a risk to the environment due to the use of methyl bromide, which is known to damage the ozone layer and increase UV radiation.

Both heat treating and fumigating are methods to eliminate pests from wood pallets, but heat treating is preferred because:

- It does not involve toxic chemicals.

- It enhances pallet durability by reducing moisture content.

- It makes pallets less prone to decay compared to fumigated pallets.

Overall, heat treated pallets offer a safer, more environmentally friendly, and durable wood solution for ship shipping needs.

Export Compliance with Heat Treated Pallets

Heat treated pallets are primarily utilized for exporting goods outside of the United States. These pallets help mitigate delays and costs associated with customs rejections by ensuring compliance with international pest control standards. Compliance with international shipping standards is simpler with heat treated pallets as restrictions on chemical treatments like methyl bromide increase.

After treatment, the pallets receive an IPPC stamp indicating compliance with international standards. The IPPC stamp includes a country code and a registration number for traceability. These markings indicate compliance with ISPM-15 standards after heat treatment, ensuring that the pallets can be safely accepted in international markets and facilitating smooth customs clearance.

How Long Does Heat Treatment Last?

The longevity of heat treated pallets can range from 3 to 10 years based on usage and storage conditions. The heat treatment lasts for the lifetime of the wood pallet, ensuring continued compliance and safety throughout its use. However, if a part of the wood pallet is removed and repaired, it is no longer considered certified and needs re-treatment to ensure compliance and integrity.

Re-treatment is essential to maintain the effectiveness of the heat treatment and to ensure that the pallets continue to meet international standards. By adhering to these guidelines, businesses can ensure that their pallets remain compliant and effective for as long as possible, providing a reliable solution for their shipping needs.

Choosing the Right Supplier for Heat Treated Pallets

Choosing the right supplier for heat treated pallets is crucial for compliance with shipping regulations and maintaining high-quality standards. A reliable supplier should adhere to ISPM-15 standards and have the necessary export certifications. Understanding the supplier’s production capacity, including daily output and scalability, helps avoid delays and ensures consistent fulfillment of shipping needs.

Additionally, it is vital to inquire about the types of pallets a supplier offers, including their options for new, recycled, and heat-treated pallets. Having a dedicated account manager and prompt response times for inquiries can significantly improve the supplier-client relationship and ensure that any contact issues are addressed swiftly.

By carefully selecting a supplier that meets these criteria, business can ensure that they receive high-quality, compliant heat treated pallets that meet their shipping needs.

Summary

In conclusion, heat treated pallets are an essential component of modern shipping solutions, offering numerous benefits such as enhanced durability, cost efficiency, and improved environmental and health safety. Compliance with international standards like ISPM-15 ensures that goods can be transported safely and efficiently across borders, protecting global agriculture and ecosystems. By understanding the process of heat treating pallets and choosing the right supplier, businesses can optimize their shipping operations and ensure the safe and compliant transport of their goods. Embracing heat treated pallets not only safeguards your cargo but also contributes to a more sustainable and responsible global trade environment.

Frequently Asked Questions

What is the primary purpose of heat treating pallets?

The primary purpose of heat treating pallets is to eliminate pests, ensuring product quality, hygiene, and safety in international shipping. This process is essential for compliance with international regulations.

What temperature and duration are required for effective heat treatment of pallets?

To ensure effective pest elimination, pallets must be heated to at least 140 degrees Fahrenheit for a minimum of 30 minutes.

What is ISPM-15 and why is it important?

ISPM-15 is an international standard that requires the treatment of wood packaging materials to prevent pest spread, making compliance essential for safe international shipping. This standard helps protect ecosystems and agriculture across borders.

How long does the heat treatment last on pallets?

The heat treatment on pallets lasts for their entire lifetime, which can be between 3 to 10 years, depending on usage and storage conditions.

What are the environmental benefits of using heat treated pallets over fumigated pallets?

Heat treated pallets offer significant environmental benefits by avoiding toxic chemicals like methyl bromide, thus minimizing health risks and environmental damage. Furthermore, they improve the wood’s resistance to mold, fungi, and decay, contributing to sustainability.